Welcome to Eco Green, where innovation meets environmental protection. For over 20 years, we have been dedicated to manufacturing top-tier oil absorbents, helping companies and individuals combat oil spills and decontaminate polluted waters and lands. With a loyal customer base exceeding 1,000 and a quality satisfaction rate of over 90%, Eco Green is your trusted partner in environmental preservation.

Introduction Oil-Water Separator Guide

An oil-water separator in the UK is designed to remove oil and other contaminants from water, ensuring that the water can be safely discharged or reused. These separators are essential in various industries, including manufacturing, automotive, and marine, where oil contamination is common.

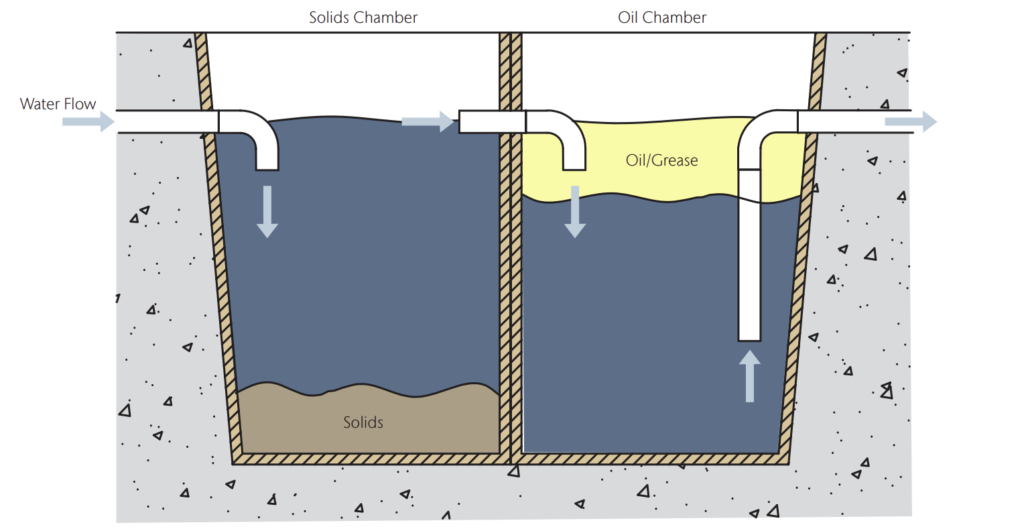

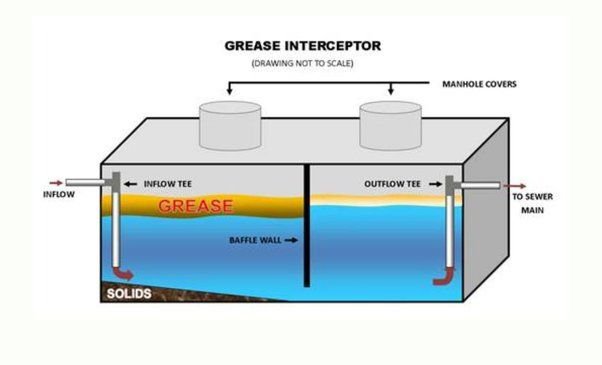

At Eco Green, we offer a range of oil-water separators engineered for efficiency and reliability, among the best absorbent oil in the market. Our separators use a combination of gravity separation and filtration to remove oil from water effectively. The process begins with the contaminated water entering the separator, where the difference in density between oil and water allows the oil to rise to the surface. The separated oil is then collected for proper disposal or recycling, while the cleaned water is discharged. With a satisfaction rate of over 90%, Eco Green is your trusted partner in environmental preservation.

How to Work an Oil-Water Separator

Operating an oil-water separator is straightforward, especially with the high-quality products from Eco Green. Here’s a step-by-step guide on how to use our separators:

1. Installation: Place the separator where it can quickly receive contaminated water. Ensure that the inlet and outlet connections are secure.

2. Startup: Mix the separator with water to the appropriate level. It helps to prime the system.

3. Operation: As contaminated water enters the separator, it flows through the internal chambers, where gravity and coalescing filters work to separate the oil from the water. The oil, being less dense, floats to the surface and accumulates in the collection area.

4. Maintenance: Regularly check the oil level in the collection area and remove the accumulated oil. Inspect the filters periodically and replace them as needed to maintain optimal performance.

5. Disposal: Properly dispose of the collected oil following local regulations. The clean water can be safely discharged or reused, depending on your needs.

To enhance the efficiency of your oil-water separator, consider using oil absorbents such as oil absorbent pads. These pads are among the best absorbents available and can help quickly soak up any remaining oil residues, ensuring your water is as clean as possible.

Eco Green is committed to providing environmentally friendly solutions that make oil spill management more accessible and practical. Our extensive experience and dedication to quality ensure that you receive products that meet and exceed your expectations.

You can shop with Eco Green today and join over 1,000 satisfied customers in protecting the environment. Together with You, we can make a significant impact on reducing pollution and preserving our natural resources for future generations.

Oil-Water Separator Guide Chart

We have developed a comprehensive guide chart to help you choose the best oil-water separator for your needs. This chart outlines the specifications and capabilities of our various models, making it easy for you to find the perfect solution. Whether you need a small unit for a workshop or an extensive system for an industrial site, our guide chart provides detailed information on capacity, flow rates, and efficiency.

Our separators are designed to be user-friendly, ensuring that even those with minimal technical knowledge can operate them effectively. Additionally, we provide full support and maintenance services to ensure your system remains in optimal working condition.